What is New in Printed Circuit Board Making?

3D PCB Printers

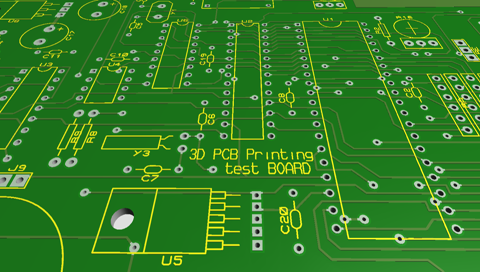

If you were a hobbyist and wanted to make a quick one-off PCB at home, there are a number of steps that you must follow. After preparing the PCB design, you then print out the separate 2D PCB layouts using a paper printer in PCB Making and then go through the whole ironing and etching process for you to get your board ready with all the required copper traces. This practice is slowly going to disappear.

The well-known Mechatronics 3D Printing technology is slowly establishing its roots in PCB technology. This is what shall truly be, the Rapid PCB Prototyping. 3D PCB Printing not only makes the PCB but it also does the Printed Circuit Board Assembly (PCBA). This reduces what was a weeks or days exercise into about one-hour job. The only downside of these machines is that they are currently too expensive that most hobbyist will not afford.

Flexible PCBs Making and Wearable Technology

There has been an increase in the need to bring electronics closer and closer to our bodies. This is majorly due to health reasons. It is becoming more and more important to monitor human health every now and then rather than waiting for a normal doctor checkup or waiting until you actually feel sick. Flexible PCB (FPCB) has come in handy to leverage the wearable technology. The use of traditional rigid PCBs Making in wearable technology is getting minimized day after day. The copper tracks are now being build up and they are being made thin and thinner. This is making wearables more comfortable to put on and more efficient in operation, especially were the wearable sensors data is to be transmitted wirelessly.

High Density Interconnects PCBs (HDI PCBs)

There is obvious need for miniaturization. Whether you want to make a board for a wearable application, a new computer board or just an Internet of Things (IoT) device. Electronics components are required to be very small to occupy the smallest space with a superior performance in PCB Making. This cannot be achieved by the conventional PCB routing methods. With HDI technology, PCB components can be packed very closely to each other and yet function even better. With the help of microvias, which are about 140um, components can be densely packed to as close as 100um. This is achieved without compromising the quality of electrical signals involved.

Comments

Post a Comment