When designing a PCB that will be assembled by a pick and place machine, the first thing you probably need to check and keep in mind is the manufacturers capabilities. This is because the manufacturers limitation is the one that entirely limits the sort of PCBs which can be produced. All PCB PCBA manufacturers have their design rule check for PCB design. Your PCB design then should conform to the manufacturers design specifications and should be within the manufacturers limitations.

Having understood the manufacturers design rules, the next thing you want to do is to choose a PCB design software that will help you make your design in accordance to the manufacturers specifications. One way of doing this is to put together a script or a program that defines all the PCB governing rules and so it captures all the errors that come as you make the PCB. Most PCB manufacturers provide a readymade script that you can add to your PCB design software which will then capture the errors during a design rule check.

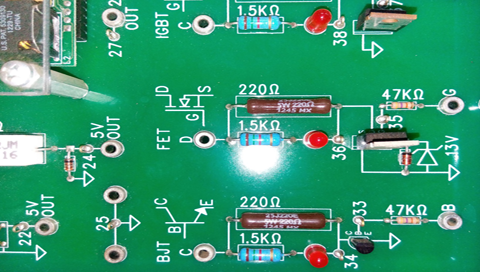

For a pick and place PCB design, you must aim to eliminate all the through hole PCB components and replace them with surface mount components (SMT). This will make it easy for a pick and place machine to easily pick and place the components on the PCB (PCB Assembly). Any manual work is eliminated or at least drastically reduced. In addition, turning the PCB board components into SMT will drastically reduce the price for your PCB.

Another tactic for pick and place PCB design is to reduce the number of components on the board. For example, if you have many resistors in series, see how you can combine them into one resistor. On the same note, make sure that you choose larger components and always go for the most common components as it will be manufactured much easier.

Comments

Post a Comment