You can etch a PCB by yourself, in a lab or even at home, through a simple and inexpensive production process.The etching pcb process is therefore effective for a small workshop. There are however some issues to consider:

1.There is a risk of injuries due to the chemicals involved.

2.The quality of the results depends on several factors which you won't be able to master completely the first time. This can be somewhat compensated by using good machinery.

3.There is the problem of waste disposal. Toxic chemicals require a proper disposal service.

To learn how to etch a PCB, make sure that your Fritzing PCB design is complete and exported as an etchable PDF or SVG, then follow these instructions.

Anyway,have a PCB design first

you can design your PCB in anything you want. A lot of people use EAGLE, but I prefer to do it in Adobe Illustrator. It doesn't matter what you use, these tips should still help.

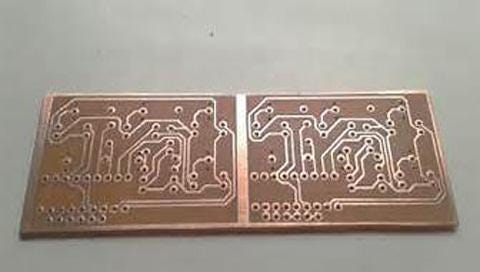

Second: Preparing the Board and the Toner Transfer,because you have to transfer the toner on the magazine paper to the copper board.Make sure your copper board is as clean as possible and don't handle it too much and also make sure your iron is as hot as possible but with the steam function turned off.

Etching. The things you need to pay attention are:

1.The choice of Etching solution

>Sulfuric acid-hydrogen peroxide etching solution:It can be used for micro etching before the plating. It has been used in PCB etching in recent years.It is characterized by non - Corrosion of tin - lead alloy, the solution is very simple, the only product after the etching of copper sulfate.The etching solution can be recycled and recovered to obtain high purity copper sulfate crystal.Therefore, it can reduce waste water emissions and environmental pollution,It is a promising etching solution.

Etching mechanism: H2O2→H2O+(O)

Cu+(O) →CuO

CuO+H2SO4→H2O+CuSO4

总反应式为:Cu+H2O2+H2SO4→2H2O+CuSO4

>hydrochloric acid-hydrogen peroxide etching solution:Simple operation, fast, low cost,especially suitable for producing large area PCBs

2.Photolithography was used to coat the conductor circuit on the circuit board and many of the steps in the process used plasma technology.

First, the entire surface of the metal layer need to be coated, and also the photoresist layer is coated. The photoresist layer is exposed and developed.Meanwhile, the structure of the subsequent conductor circuit is still covered by photoresist.

Next, remove the metal layer from the uncovered area by Reactive Ion Etching (RIE).

Then, Remove Toner:the photoresist on the conductor circuit is removed by plasma etching in an oxygen plasma

Drilling & Tinning

You'll now need to drill all the holes in the board. I suggest getting a drill press accessory for your dremel to do this, although I'm sure you could do it fine with a steady hand and a bit of patience.

I drilled all the LED/cable holes with a 0.8mm bit and the screw holes with M3 bit.

Till now,an etched PCB is basically finished.

From wellpcb

Comments

Post a Comment